What is Textile Printing?

Textile printing is the technique of applying colour and decorating a wide range of fabrics in certain patterns and designs via the application of pigments, dyes, or other similar chemicals.

Importance of Textile Printing

It is the process of textile printing that helps manufacturers produce a varied range of prints and styles to cater to the diverse needs of end customers. The importance of dyeing and printing in textile printing is undeniable. Dying is the technique of colouring the entire fabric evenly in one colour, whereas printing is the method of applying one or more colours to the fabric in specific portions only and in clearly specified patterns.

Different Types of Textile Printing

These are some of the many methods or types of textile printing:

• Direct printing – In this method, the colour is applied directly to the surface of the fabric. It is also referred to as overprinting when the colour of the print paste is deeper than the surface colour of the fabric.

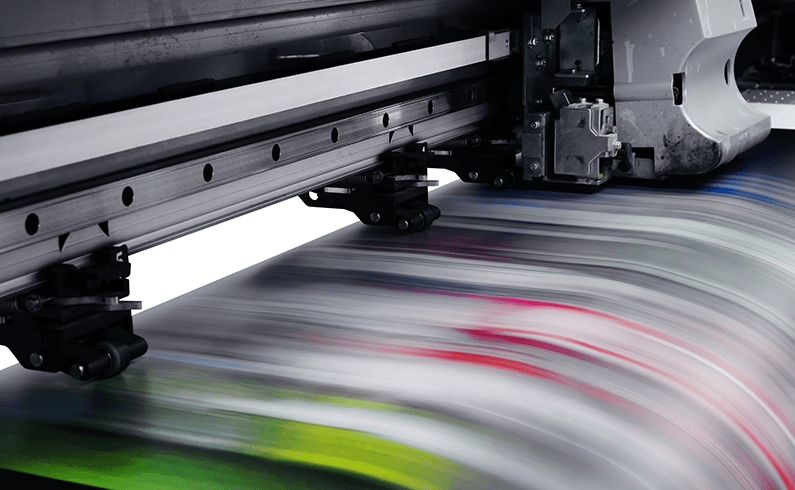

• Digital textile printing – Digital printing on fabrics is also known as direct-to-garment or DTG printing. It is a method of printing on fabrics and clothing that employs specialised or customized inkjet technology.

• Resist printing – This method, in contrast to discharge printing, includes the application of resist paste to the textile. After then, the fabric is coloured. The spot where the print paste has been put prevents dye from penetrating the fabric’s surface, resulting in a different hue for the design.

• Transfer printing – This method, in contrast to discharge printing, includes the application of a resist paste to the textile. After then, the fabric is coloured. The spot where the print paste has been put prevents dye from penetrating the fabric’s surface, resulting in a different hue for the design.

• Discharge printing – Also known as extract printing, discharge printing in textile involves the application of print paste to the pattern area on a pre-dyed fabric. The print paste either entirely removes the dye from the fabric to produce a white colour (white discharge) or leaves a distinct colour (colour discharge) on already dyed fabric.

Pidilite and Discharge Printing on Fabric

A Dry discharge printing technology uses ready-to-print paste and a discharge printing chemical [activator] to print on cloth.

Pidilite provides the following Perase Discharge Printing System:

• Perase Discharge Paste W CRT

• Perase Discharge Paste C CRT

• Perase Activator SPL

• Perase Activator HP

Guideline Recipes:

For white textile printing on coloured substrate:

- Perase Discharge paste W CRT 92 – 94 %

- Perase Activator HP / Perase Activator SPL 08 – 06 %

For colour textile printing on coloured substrate:

- Perase Discharge paste C CRT 80 – 88%

- Texcron pigment emulsion 5 – 10 %

- Perase Activator HP / Perase Activator SPL 6 – 8 %

- Pidifix or Pidifinish Fixer 0.5 – 2.0 %

The following are the key characteristics of the Perase Discharge printing system:

- It produces prints that are brilliant, soft, and tack-free, with excellent ground coverage.

- It is appropriate for woven and knit materials.

- Pumpable viscosity and smooth flow qualities allow for easy application on all types of printing equipment [flatbed and rotary].